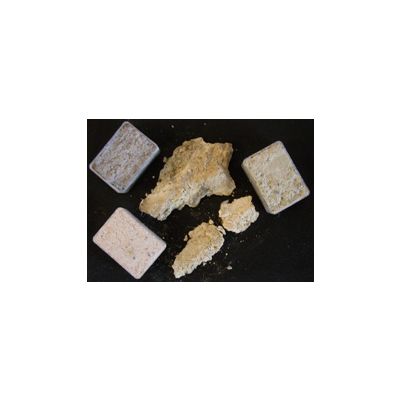

Pre-Mixed Fat Lime Mortar (Rhondda)

Our pre-mixed fat lime mortar is made from a high calcium lime/non-hydraulic lime blended with carefully selected aggregates. The different aggregates help to provide a good range of colours and textures. Our 'Rhondda' is ready to use mortar for both building and pointing.

Estimate how much you will need by using our calculator!

Collection

Next Day Pallet

Economy Pallet

Parcel Delivery

Our pre-mixed fat lime mortar is made from a high calcium lime/non-hydraulic lime blended with carefully selected aggregates. The different aggregates help to provide a good range of colours and textures.

These lime mortars require exposure to Carbon Dioxide in the presence of moisture to harden. It is therefore important to use these mortars at an appropriate time of the year and to protect them from drying too rapidly. Application guides are printed on the bags and available below, we also have an excellent telephone support service for customers, so don't be put off from using them - the results are well worth it!

Properties : the most flexible and vapour permeable/breathable of the lime product family, so highly suitable for solid wall construction buildings, old garden walls etc.

Preparing The Mortar

- Do not add water - a premixed mortar when purchased may appear too dry. It must be ‘knockedup’ (the process of chopping, beating and turning) which will release the water already present in the mix. Water should only be added CAUTIOUSLY if the mortar is still too dry AFTER ‘knocking-up’. For small quantities, an ordinary drum mixer will be sufficient, if you are going to mix large quantities then a mortar mill is recommended (Tŷ-Mawr has several types to hire/ purchase see www.lime.org.uk).

- Keep the mortar stiff - mortar for pointing should be kept stiff and dry in order to compress it into the joint without smearing. Take care not to get mortar on the face of the brick/stonework. Mortar for laying/bedding work needs to be a little wetter but should still be kept as stiff as possible to avoid excessive shrinkage. The mortar needs to be just wet enough to be workable.

Pointing

Preparing The Surface

- Loose existing mortar must be raked out and dust removed, usually to a depth equal to twice the width of the joint. Sound mortars should be left.

- Assess the moisture content of the background - for dry substrates, dampen all stones/bricks and adjoining surfaces by spraying with water or immersing in water, otherwise they will ‘suck’ the moisture out of the mortar before it sets, causing it to turn to dust. However, if the wall is already wet, do not add more water, in fact it may be necessary to encourage it to dry out first.

Application

- Do not overwork mortar - pointing mortar should, initially, be pressed into the joint without any attempt to ‘finish it’.

- Large holes should be packed with gallets/pinnings - small pieces of stone or bricks, as large volumes of mortar will shrink.

- Bring out mortar joints in layers of up to 10 - 15mm thick to allow carbonation, using a pointing or finger trowel from a small plastic hawk.

- Leave each coat until it is hard i.e. set, but not dried out - the mortar should be ‘too hard to dent with a knuckle yet soft enough to mark with a thumbnail.’

- It should be left to ‘stiffen up’ for up to 24 hours (depending on the speed of drying). Only then can it be worked over to compress it (to overcome shrinkage) and to produce the required finish.

- Brush when firm with a churn brush, to achieve desired finish.

- We do not advise the use of pump-action mortar guns.

Suitable For

- Pointing - Brickwork

Coverage Rate

- 2.5sqm per 25kg bag - Brickwork

- Gives a consistent, accurate mix hence removes the potential for mixing and gauging errors on-site.

- Minimises waste - enables you to 'knock-up' as much as you require in a day, anything left over can be reused, so nothing goes to waste.

- Helps to keep the site organised and clean.

- colour and texture variations can be accommodated making sure regional variations are maintained. High quality aggregate selection produces a very workable 'fatty' mix, minimising shrinkage.

- This product is made in our manufacturing yard that operates under our Quality Management System.

- This is a recycled aggregate (made from crushed building material), due to this colours can very slightly between batches.

- You should be aware that aggregates occasionally run out, e.g., if a quarry closes. If it is important that you maintain the colour for the whole job, then you should ensure that you purchase sufficient supplies where possible.

25kg bag

Tonne Bulk Bag